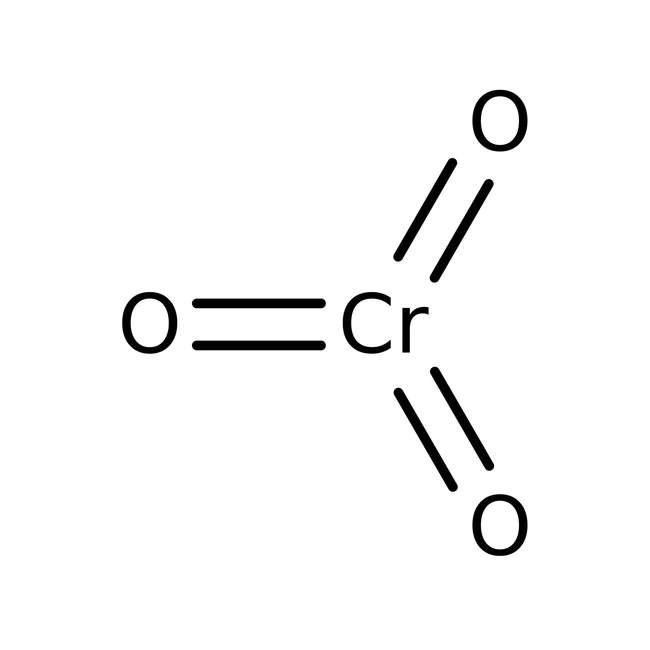

Molecular Formula:CrO3

Molecular Mass:M=99.99

CAS No.:1333-82-0

Technical Data:

Component | Content | Unit (%) |

Chromium Trioxide / CrO3 | Min. 99.7 | % |

Sodium / Na+ | Max. 0.2 | % |

Sulfate / SO42- | Max. 0.2 | mg/kg |

Chloride / CI- | Max. 100 | mg/kg |

Ferro / Fe | Max. 50 | mg/kg |

Insolubles | Max. 100 | mg/kg |

Property and Application

? Most other manufacturers produce Chromium Trioxide by a reaction of Sodium Dichromate with concentrated Sulphuric Acid at elevated temperatures. This results in molten Chromium Trioxide. The flakes are subsequently shaved off a cooling drum. BROTHER CISA produces Chromium Trioxide by means of an electrolytic reaction, resulting in the formation of crystalline Chromium Trioxide out of an aqueous solution. Therefore, sulfate content and insolubles in finished product are lower than competitors.

? BROTHER CISA Chromium Trioxide Crystals (compared to the bigger flakes) result in an easy dissolution when preparing for galvanic baths (less downtime) and reduce dust development during handling (improved workers’ safety).

? Functional plating with decorative effects: Sanitary fittings (water taps, shower heads, etc.), some externally visible plated parts in cars or two wheelers (bumpers, logos, etc). BROTHER CISA Chromium Trioxide results in a very bright and glossy shade and very

good adhesion to the substrate (both plastic as well as metal substrates).

? Hard chrome plating: Piston rings, shock absorbers, printing rollers, hydraulic cylinders, etc. BROTHER CISA Chromium Trioxide shows high corrosion resistance, excellent surface hardness, homogeneous layer properties even at higher thickness, no cracks (consistent thickness all over the plated area), quality stability (low reject rate), longer lifetime of the galvanic bath during the plating process (less downtimes for regeneration or changing the bath).